COMPANY PROFILE

COMPANY PROFILE

The production program builds on the long tradition, expertise, knowledge and skills of our employees at all levels of the company.

The company is now successfully operating in these areas.

- manufacture, reconstruction, modernisation and repair of passenger and freight railway vehicles

- manufacture, reconstruction and modernisation of tramcars

- manufacture and repair of historic railway vehicles

- engineering production of rotating parts including induction hardening, weldments and machining of castings for the railway industry

Our products and services have found satisfied customers in the Czech Republic, Slovakia, Poland, Russia, Croatia, Austria, Germany, Switzerland, France, Belgium, Spain, Finland and UK.

HISTORY

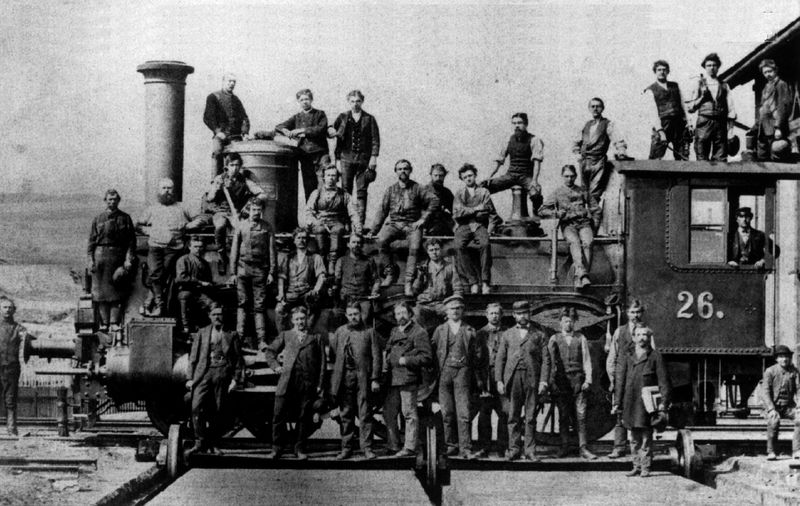

The development of railway transport in the second half of the 19th century and the establishment of the Olomouc-Krnov-Opava railway line presupposed the building of technical facilities for the maintenance of rolling stock. The favourable geographical location of Krnov as a future railway junction station meant the establishment of the “Mechanical Service Facility for Railway vehilces Maintenance”, which started its activity on 1 October 1872 at the same time as the Moravian-Silesian Central Railway started its operation.

During the long period of its activity in repairing steam locomotives, passenger and freight vehicles, including the production of spare parts for repairs and carriages, the workshops went through various phases of development in terms of organisation and management. On the basis of social changes after 1989 and the decision to privatise the Railway Repair and Engineering Works in 1992, Krnovské opravny a strojírny s.r.o. was established on 1 September 1992.

PRESENT

The company Krnovské opravny a strojírny s.r.o. successfully continues the rich history of the Railway Vehicle Repair Workshops and with its approximately 420 employees is the second largest employer in the city of Krnov.

After the privatization of the company, extensive investment began, focused specifically on:

- the quality of surface treatments (blasting and painting boxes for railway vehicles)

- expansion of the technology for the repair of four-axle passenger vehicles (transfer station, electrical testing room, etc.)

- quality of engineering production (CNC machining centres, CNC hardening machine, metallographic workplace, welding plant)

A significant milestone in the transformation of the repair plant into a manufacturer of railway vehilces was the signing of a contract on commercial, technical and production cooperation with the business engineering company Pragoimex a.s. in 2001. Together with the contractual partners – Pragoimex and the design office VKV Praha s.r.o., we form the TW Team Alliance, which supplies new tramcars for public transport.